|

|

We

are the People that are FREE! |

|

|

From

The Coastal Passage, issue #29 |

|

PASSAGE PEOPLE TAKES A LOOK

AT BOBS BAREBONES PROJECT |

|

Whilst

this project occupies the editors time Passage People may have

to be restricted to pics and stories of those who stop by to

help! Want your pic on the back page? Bring sandpaper! |

|

It first started as a realisation

that I was talking myself into a plan that I was meant to be

researching for others. In TCP # 13 I did an article “The

Multi Eye for the Mono Guy”. The piece was a great success

and since I posted it to the web site (see technical articles)

has been a steady download for tens of thousands of readers.

At that time two things had become apparent, first was that TCP

was definitely not going to go away. My little hobby had gone

wrong and I was no longer a happily retired person, aspiring

to peaceful old fart status and.. it was becoming just as clear

that our beloved old “WhiteBird” was exactly the wrong

kind of boat for this now uncontrollable life style. Big thundering,

high maintenance steely with not quite enough room to fit the

gear for publishing TCP. A great boat for our original purpose,

blue water with a circumnav up my sleeve, but a total encumbrance

for our new reality, coastal cruising and workaboard. Besides,

(incidentally of course) I had been on a few faster boats and

I liked it! |

|

So, what is the perfect solution?

First on my list of required attributes was low maintenance.

That means plastic. Now before I start WWIII with the fans of

alloy or other materials, I grant there is some subjectivity

in the choice but overall a glass fibre composite fits the bill

best.

The new boat would have to have room for the computers and printers

used to publish TCP and still be comfortable for long term liveaboard.

A catamaran of about 40 feet would have the accommodation space

in a bridge deck configuration to allow this.

The boat would have to be affordable... BUGGER!! It was easy

up till now. A new or good condition second hand cat of that

size and construction is in the $300K to $500K range even for

our modest fitout requirements. This kind of expense just couldn’t

be justified. The only way out is to build her. But another problem

is time.. or the shortness of it. To simplify, graceful curves

would have to be substituted for lines and flat panels but there

just wasn’t a design on the market that suited the narrow

criteria perfectly. This was Bob Oram’s kind of thing and

I was heading that way on a property search anyway, so I took

my crude sketches and cruder ideas and drove from Bowen down

to Hervey Bay. |

|

|

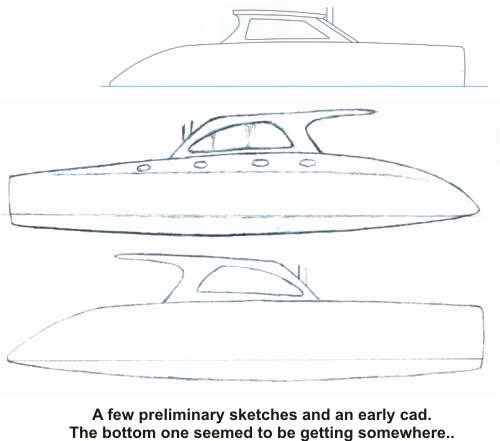

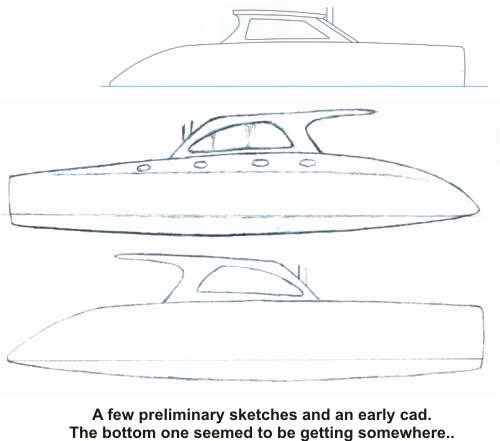

I found myself sitting with Bob

Oram in front of his powerful modern computer working on a program

right out of the DOS dark ages. “Plyboat” is something

you can download for about the cost of a slab of beer but the

thing worked for designing the hulls. We did have some arguing

about sheer. Bob’s first version was quite flat like the

44C but I liked the effect from his 38 Mango II design. A halfway

point was printed out but it still looked flat to me until Bob

advised to take the paper and hold it somewhat edgewise toward

my face and look ‘down’ the sheer and he was right.

Bob then pointed out the similarity in hull profile to “Dog

on Cat”, a boat he drew several years ago. A boat I had

seen and admired. With the objective of simplicity, a cabin top

was drawn as well but has since been replaced and may be modified

again. The hulls are the big thing, the cabin design can be changed

almost on a whim with this style of construction.

Another trip south with a cabin sketch and a few other ideas

and questions... and the “39C” took shape. With Bob’s

guidance the lines were refined and improved. I am proud to have

contributed to the look and marketing philosophy (I believe this

boat suits a lot of potential builders, amateur and professional)

but there is no way I would commit this kind of money and effort

into something that didn’t have professional experience

behind it. Bob actually made her into a boat that should work

well and I believe address’s a vacuum in the market. |

Size: I wanted a boat that I felt Kay and I could handle

and as stated earlier, would be big enough for the gear. About

40 feet seemed right but... many marinas are getting touchy about

berth sizes and because many marinas use 12 metres as a break

point in price... 11.98 metre (39’ 4”) is perfect.

I won’t have to lie to the marina office! (Like I used to!)

Material: Bob Oram and I had much discussion about this.

Whilst Bob was in favour of Duflex panels from the start because

of the speed of build and stiffness, FGI had a very attractive

price on foam at the time. I figured out the costs and it seemed

that foam and vinylester resin and glass would come out to just

over half of the cost of the balsa core Duflex panels from ATL.

I had talked to designer/builder, Bob Burgess earlier who had

advised how to use that stuff for a flat panel boat. He suggested

lofting up a full length panel of foam on a flat surface and

have two guys working laying the glass. One mixing resin and

spreading and the other wetting the cloth in, then trimming edges

with a Stanley knife whilst green. Even so it would take more

time than the few days it took us to glue ATL panels together

and there would also be the problem of fumes. But then the epoxy

like that used on the ATL panels runs a risk too. I know people

that claim they have almost killed themselves with epoxy poisoning

building a boat. It’s an acquired toxic reaction. Some get

it and some can swim in the stuff. On the positive side of the

panels is that the bulk of the epoxy work is done at the factory.

I considered the options carefully and decided to go with the

Duflex panels from ATL but I ordered only the materials to the

sheer. The decks, cabin and numerous other bits can be done with

a variety of other materials, foam sandwich, strip plank, plywood,

and polypropylene honeycomb for example, or finish the lot with

Duflex.

Keels or Boards: This is one area I opted for what could

be more complexity. Boards may increase build time over keels

and take up some hull space BUT... they should permit a higher

point of sail and less wetted area, not to mention a ridiculously

skinny draft.

Auxiliary power: For cost, simplicity, and weight, the

twin 4 stroke outboard option is right for us.

Cabin: The first sketches showed a very simple thing that was

intended for the easiest construction. Flat panel sides with

an overhanging roof, something like a garden shed frankly. That

later was modified after I thought about how panels could be

curved with relative ease to enhance aesthetics. While Bob and

I were at the computer it occurred to us that reducing the angle

of the forward part of the structure would carry it over the

two forward cabins... not conventional, but why not? At least

for now it sounds like a good idea but could be adjusted later.

Fitout: Our experience fitting out WhiteBird gives confidence

that this can go quicker and cheaper than you might think. Except

for the galley and main cabin it might be little more than a

coat of house paint. No fairing except to clean a stuff up perhaps.

Well placed small bits of fine timber and white surfaces can

work wonders. We equate comfort with a lack of clutter... so

we plan to live in luxury. I noticed Bob drew in a holding tank

but I told him we already have a bucket! He insisted....

What About the Money? Here is the scoop so far. The partial

kit of duflex panels with accessories for gluing and taping has

cost $32K AUD. The full kit including bridgedeck cabin top would

come in at about $52K but that still doesn't include materials

for boards and temporary frames and forebeam etc... Firgure another

$8000. If I can get an assembled shell to lock up for $65K, I've

won. I’ve allowed a budget of $150K total but I hope we

will beat that. It will depend on the accessories we want, like

a screacher and furler. ... or...

How have we gone so far...? Whilst ATL have a reasonable

reputation our luck wasn’t good. Maybe it was because our

parcel was shipped out on the eve of the holiday season before

they closed for several weeks. Whatever the case we have some

quality control faults that I don’t think should have been

allowed to ship and I don’t yet know how to quantify. Hopefully

this won’t slow the project much but it was a disappointing

way to start. The TCP web site has details

of our problems and progress with a continuing log with photo

gallery and comments along the way. |

|